UV Diffusers Explained

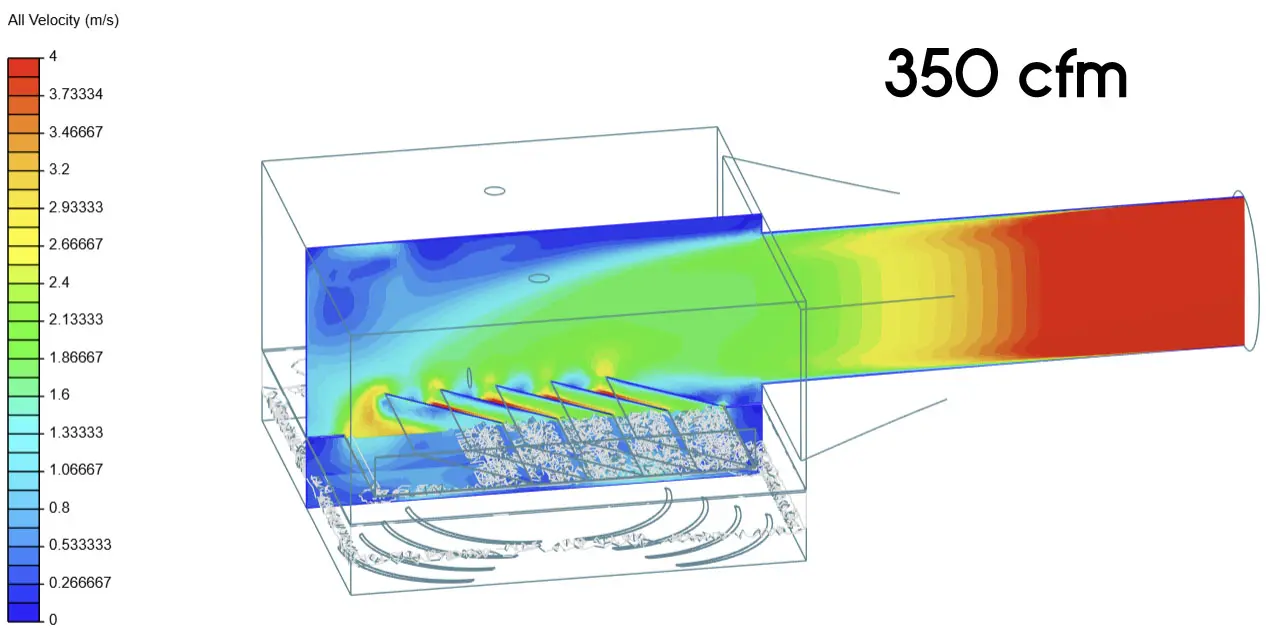

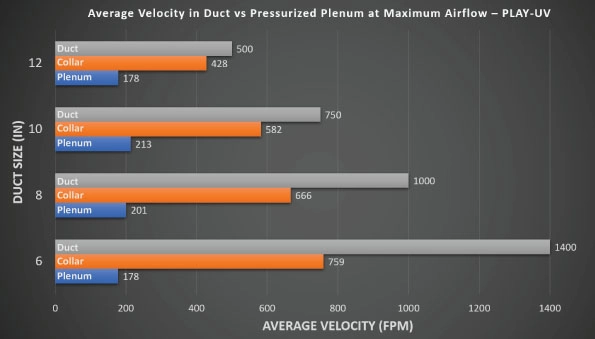

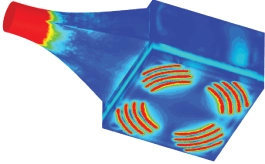

Air velocity in ventilation ducts and air handling units is very high, which makes it challenging to achieve proper UV-C irradiation and air purification

Virus particles passing through ducts at high speed are not exposed long enough to UV-C rays to be properly neutralized, the exposure time is too low

With UV Diffusers, UV-C irradiation happens at the very end of the duct line, where the air velocity is at its lowest

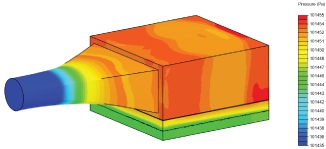

Then we pressurize the air inside the diffuser

Decreasing the air velocity even more

Virus particles are now passing through UV-C light at low speed

Multiplying virus and bacteria exposure to UV-C light, and irradiation efficiency

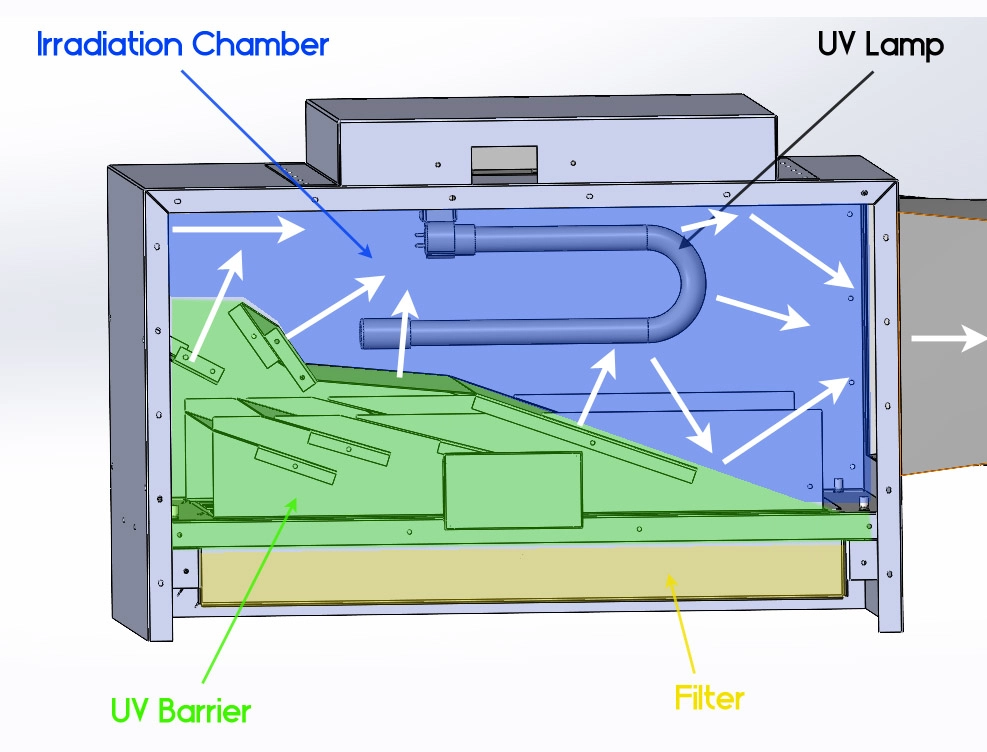

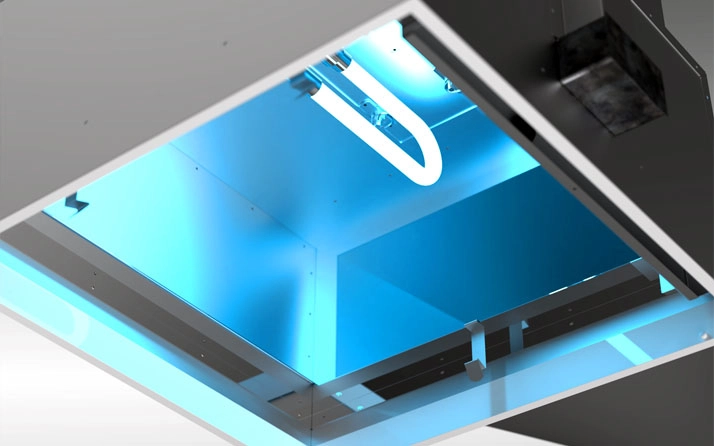

The air first passes through the irradiation chamber which has a built-in UV-C lamp. The configuration of the chamber, the angles and materials reflecting the light, as well as the airflow passing through the chamber: everything has been designed to boost UV-C irradiation inside the chamber.

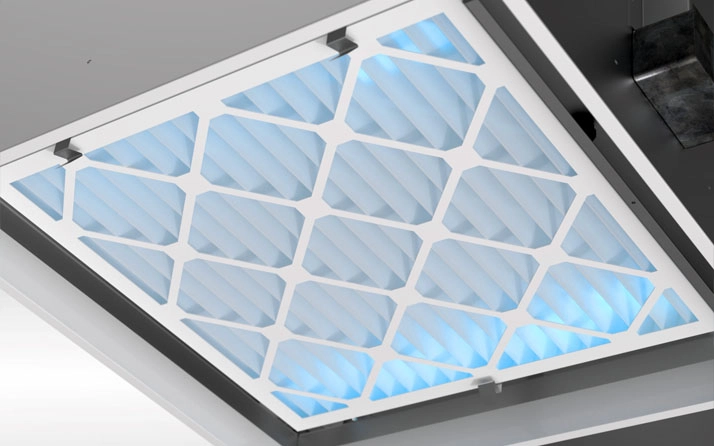

Once most microbes are deactivated, the air then passes through a MERV-9A filter to catch larger particles like dust, mold spores and other allergens.

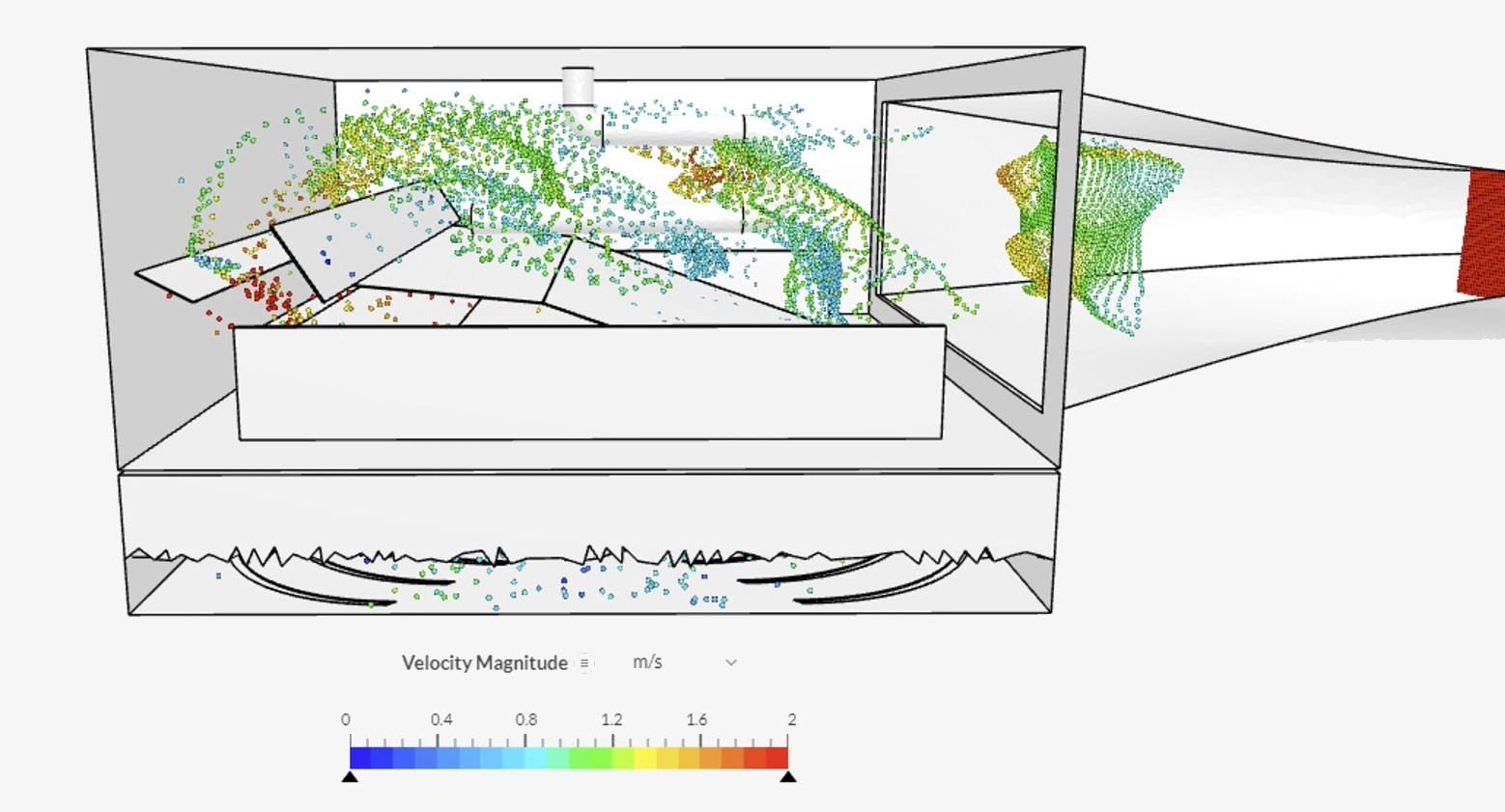

The last yet very important step is to distribute the purified air in the room as efficiently as possible

All UV diffusers distribute the air with a high discharge velocity, ensuring proper mixing of room air even at lower air volumes. This is important in order to remove as much contaminated air as possible and maintain low levels of microbial concentration in the room.

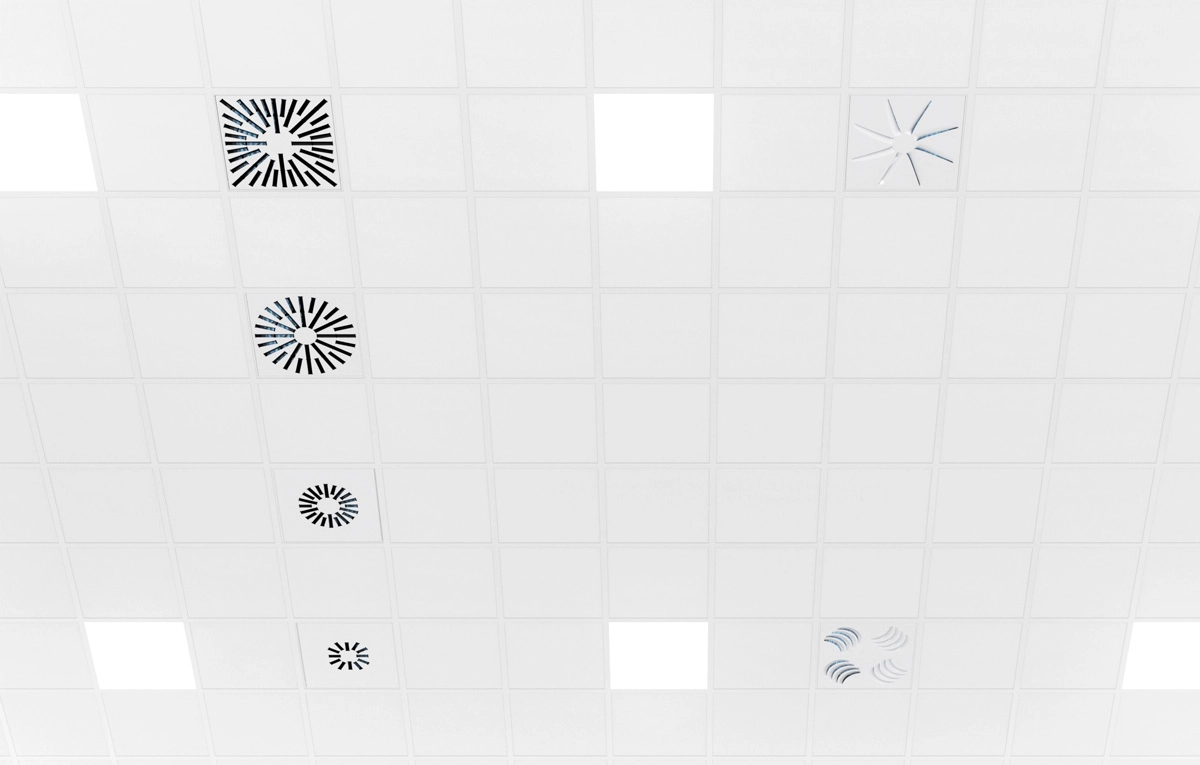

Adjustable and high induction swirl diffusers, for airflows between 50 cfm and 550 cfm, there’s a perfect UV Diffuser for every commercial application